- Home > Products Catalog > Milling > Face and side milling cutter

- Face and side milling cutter

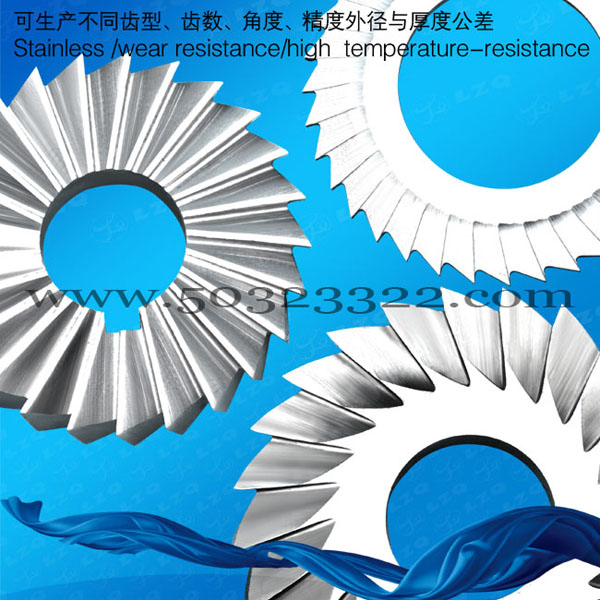

Molding three-face cutter, R profile milling cutter

|

|||||

|

E-samples: P143 |

Details

Molding three-face cutter, R profile milling cutter

Copying, downloading and reprinting unscrupulously is prohibited

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance.

If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 8~10 Million turnover stock articles such as raw material ,semi-products, finished products in ordinary year , we are capable to produce according to drawing or sample provided by customer, so as to present you a favorable cost-performance ratio…Welcome to visit our factory.

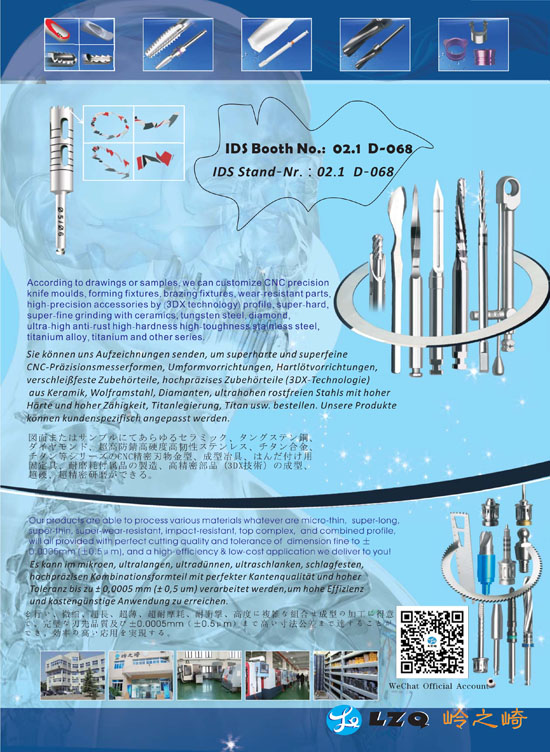

We can produce different size tolerance and compound profile products according to drawings and samples.

Our company supplies every kind of solid ultra micro-grain quality carbide sliiting cutter with different tooth shape such as direct tooth, radius tooth, staggered tooth, high-low tooth, semi-circle keyboard milling cutter, T-type slot milling cuttter, angle milling cutter, HSS cutting miilling cutter, side and face milling cutter. Those products are widely used in glass accessorieμm ,outer diameter tolerance in 0.03mm, side runout in 5μm and surface roughnss in 0.4μm. Those are used in a few pcs together, and have very high precision.

“A” tooth: straight tooth (ratched type)

It is mainly applied in finish milling and cutting. Its milling and cutting depth is shallow, about 3~5mm.

“AW” tooth: it is improved one based on “A” tooth. Tooth profile is left and right single inclined type. Its tooth function is same as that of “A” tooth, but its efficiency is higher.

It is mainly applied in finish milling and cutting. Its milling and cutting depth is shallow, about 3~5mm.

“AW” tooth: it is improved one based on “A” tooth. Tooth profile is left and right single inclined type. Its tooth function is same as that of “A” tooth, but its efficiency is higher.

“

B” tooth: curved tooth (cam-generated type)

Tooth profile is bending flat tooth, mainly applied to cut deep groove. The cutting resistance is stronger than

Tooth profile is bending flat tooth, mainly applied to cut deep groove. The cutting resistance is stronger than

A” tooth and the groove is deeper.

“BW” tooth: curved tooth (alternately beveled)

Tooth profile is left and right single inclined bending flat tooth, the improved one based on “B” tooth, mainly applied to cut thicker material of abnormal profile, with stronger cutting resistance, applied for general cross-cutting saw.

Tooth profile is left and right single inclined bending flat tooth, the improved one based on “B” tooth, mainly applied to cut thicker material of abnormal profile, with stronger cutting resistance, applied for general cross-cutting saw.

“C” tooth: “HI-LO” tooth (three-tooth regrinding; rough and finish tooth machining)

Its tooth profile is high and low ladder tooth profile. The difference between front and back tooth is 0.15±0.3mm. The front tooth is double-bevel, and the back tooth is flat. Its cutting efficiency is high, and can reduce cutting force when assisting in cutting saw.

“BR tooth: it is latest improved design of “B” tooth, with a fine cutting groove of about 0.4mm at the top of tooth. Its function is to re-break waste materials from cutting and sawing work pieces and to increase discharge rate, so that comparing with “BW” tooth, its cutting and sawing efficiency increases by 25%.

LZQ is an excellent OEM factory for manufacturing high precision and full finish grinding medical tools, cutters, fixtures, accessories as well as special new products. At present we are the OEM factory for suppliers who supply products of world-class brand; our main customers are also the manufacturers of medical tools and fixtures. We have been engaging in manufacturing the non-standard tooling and dies, profile fixtures and stainless steel or carbide brazed jigs and fixtures for the production of accessories in industry of airplane, naval vessels and automobile for a long time. With above advantages, we have gradually built and continued to improve advanced and comprehensive production system and enhanced all kinds of manufacturing and processing ability with precision technology. And with above production conditions, we realize the manufacturing for all kinds of tools, fixtures and accessories for medical use with processing way of high precision, high complexity and combination profile geometry. And we can manufacture according to your required dimensions, tolerances and other requirements for comprehensive profile processing of super complex and precision shape. The tools and cutters can have depth marking, different color code, different color coating, internal cooling hole and etc. We can meet any of your requirements if you like.

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC? Work piece drawing and notes, and please supply us new and old bestperformed samples.

Samples: Is it easy to blunt or break or other problems?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

- Previous:Metal slitting saw, single angle tool, single angle cutter,carbide metal slitting saw

- Next:forming groove milling cutter