- Home > Products Catalog > Milling > Molding Cutter

- Molding Cutter

non-standard cutting tools, general code

|

|||||

|

E-samples: P28 |

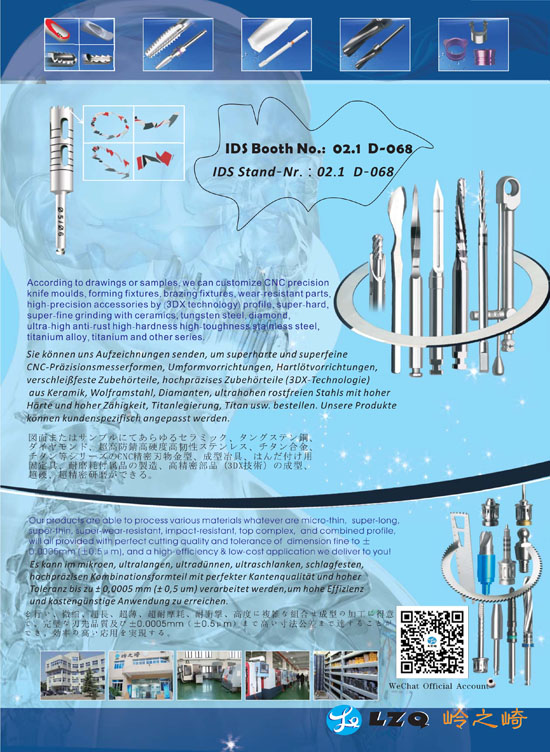

1.General\high precision product, surface finish≤Ra0.15μm.

2.Adopting advanced power high speed CNC grinder to make high precision profile grinding,it has perfect blade quality & precision tolerance.

3.Inclination\number of flute (2-flute~6-flute)\type of holder\helical angle\flute length\holder diameter\overall length etc can be machined according to requirements.

Material to be machined, Type of machining,Super-finish→ finish, semi-finish→ semi-rough, rough machining→ power (heavy) cutting

ultra micro-grain quality carbide, has excellent wear resistance, but its impact resistance is not so good. It is applicable for medium and low speed cutting of high hardness materials(HRC45°-65°) requiring thermal refining and quenching or for various materials having higher wear resistance and non-ferrous metal. Generally it is applied in good working condition\stable cutting\excellent part fixing and continuous light machining. Corresponding to ISO K10.

|

HRF10 |

HSF10 |

HTF10 |

HUF10 |

HVF10 |

HWF10 |

HXF10 |

HYF10 |

HZF10 |

ISOK |

|

HRD10 |

HSD10 |

HTD10 |

HUD10 |

HVD10 |

HWD10 |

HXD10 |

HYD10 |

HZD10 |

ISOK15B |

|

NRB10Z |

NSB10Z |

NTB10Z |

NUB10Z |

NVB10Z |

NWB10Z |

NXB10Z |

NYB10Z |

NZB10Z |

ISOK |

|

NRB10 |

NSB10 |

NTB10 |

NUB10 |

NVB10 |

NWB10 |

NXB10 |

NYB10 |

NZB10 |

ISOK |

|

SR10 |

SS10 |

ST10 |

SU10 |

SV10 |

SW10 |

SX10 |

SY10 |

SZ10 |

ISOK20B |

|

SR10T |

SS10T |

ST10T |

SU10T |

SV10T |

SW10T |

SX10T |

SY10T |

SZ10T |

ISOK |

|

MR11 |

MS11 |

MT11 |

MU11 |

MV11 |

MW11 |

MX11 |

MY11(V350) |

MZ11 |

ISOK |

|

MR12 |

MS12 |

MT12 |

MU12 |

MV12 |

MW12 |

MX12 |

MY12 |

MZ12 |

ISOK30B |

|

MR12T |

MS12T |

MT12T |

MU12T |

MV12T |

MW12T |

MX12T |

MY12T |

MZ12T |

ISOK |

|

KR121 |

KS121 |

KT121 |

KU121 |

KV121 |

KW121 |

KX121 |

KY121 |

KZ121 |

ISOK30D |

|

PR14 |

PS14 |

PT14 |

PU14 |

PV14 |

PW14 |

PX14 |

PY14 |

PZ14 |

ISOK |

|

KR141 |

KS141 |

KT141 |

KU141 |

KV141 |

KW141 |

KX141 |

KY141 |

KZ141 |

ISOK40B |

|

PR15 |

PS15 |

PT15 |

PU15 |

PV15 |

PW15 |

PX15 |

PY15 |

PZ15 |

ISOK |

|

KR301 |

KS301 |

KT301 |

KU301 |

KV301 |

KW301 |

KX301 |

KY301 |

KZ301 |

ISOK40D |

|

KR301Z |

KS301Z |

KT301Z |

KU301Z |

KV301Z |

KW301Z |

KX301Z |

KY301Z |

KZ301Z |

ISOK40E |

|

PR35 |

PS35 |

PT35 |

PU35 |

PV35 |

PW35 |

PX35 |

PY35 |

PZ35 |

ISOK |

|

PR40 |

PS40 |

PT40 |

PU40 |

PV40 |

PW40 |

PX40 |

PY40(TH15) |

PZ40 |

ISOK |

|

PRA5 |

PSA5 |

PTA5 |

PUA5 |

PVA5 |

PWA5 |

PXA5 |

PYA5 |

PZA5 |

ISOK40H |

|

NRA61 |

NSA61 |

NTA61 |

NUA61 |

NVA61 |

NWA61 |

NXA61 |

NYA61 |

NZA61 |

ISOK40I |

|

NRA62 |

NSA62 |

NTA62 |

NUA62 |

NVA62 |

NWA62 |

NXA62 |

NYA62 |

NZA62 |

ISOK40J |

|

SRA63 |

SSA63 |

STA63 |

SUA63 |

SVA63 |

SWA63 |

SXA63 |

SYA63 |

SZA63 |

ISOK |

|

NRA71 |

NSA71 |

NTA71 |

NUA71 |

NVA71 |

NWA71 |

NXA71 |

NYA71 |

NZA71 |

ISOK45B |

|

KRA720 |

KSA720 |

KTA720 |

KUA720 |

KVA720 |

KWA720 |

KXA720 |

KYA720 |

KZA720 |

ISOK |

|

PRA8 |

PSA8 |

PTA8 |

PUA8 |

PVA8 |

PWA8 |

PXA8 |

PYA8 |

PZA8 |

ISOK15D |

|

SRA81 |

SSA81 |

STA81 |

SUA81 |

SVA81 |

SWA81 |

SXA81 |

SYA81 |

SZA81 |

ISOK15E |

|

SRA82 |

SSA82 |

STA82 |

SUA82 |

SVA82 |

SWA82 |

SXA82 |

SYA82 |

SZA82 |

ISOK |

|

SRA82T |

SSA82T |

STA82T |

SUA82T |

SVA82T |

SWA82T |

SXA82T |

SYA82T |

SZA82T |

ISOK |

|

PRA |

PSA |

PTA |

PUA |

PVA |

PWA |

PXA |

PYA |

PZA |

ISOK15H |

|

PRA820 |

PSA820 |

PTA820 |

PUA820 |

PVA82 |

PWA820 |

PXA820 |

PYA820 |

PZA820 |

ISOK15I |

|

PRA820T |

PSA820T |

PTA820T |

PUA820T |

PVA820T |

PWA820T |

PXA820T |

PYA820T |

PZA820T |

ISOK15J |

|

NRA91 |

NSA91 |

NTA91 |

NUA91 |

NVA91 |

NWA91 |

NXA91 |

NYA91 |

NZA91 |

ISOK15K |

|

NRA920 |

NSA920 |

NTA920 |

NUA920 |

NVA920 |

NWA920 |

NXA920 |

NYA920 |

NZA920 |

ISOK |

|

PRA11 |

PSA11 |

PTA11 |

PUA11 |

PVA11 |

PWA11 |

PXA11 |

PYA11 |

PZA11 |

ISOK |

|

PRA111 |

PSA111 |

PTA111 |

PUA111 |

PVA111 |

PWA111 |

PXA111 |

PYA111 |

PZA111 |

ISOK15N |

|

PRA121 |

PSA121 |

PTA121 |

PUA121 |

PVA121 |

PWA121 |

PXA121 |

PYA121 |

PZA121 |

ISOK15O |

|

NRA122 |

NSA122 |

NTA122 |

NUA122 |

NVA122 |

NWA122 |

NXA122 |

NYA122 |

NZA122 |

ISOK15P |

|

PRA1220 |

PSA1220 |

PTA1220 |

PUA1220 |

PVA1220 |

PWA1220 |

PXA1220 |

PYA1220 |

PZA1220 |

ISOK15Q |

|

PRA1220T |

PSA1220T |

PTA1220T |

PUA1200T |

PVA1220T |

PWA1220T |

PXA1220T |

PYA1220T |

PZA1220T |

ISOK15R |

|

PRA181 |

PSA181 |

PTA181 |

PUA181 |

PVA181 |

PWA181 |

PXA181 |

PYA181 |

PZA181 |

ISOK15S |

|

VRA191 |

VSA191 |

VTA191 |

VUA191 |

VVA191 |

VWA191 |

VXA191 |

VYA191 |

VZA191 |

ISOK15T |

|

VRA201 |

VSA201 |

VTA201 |

VUA201 |

VVA201 |

VWA201 |

VXA201 |

VYA201 |

VZA201 |

ISOK15U |

|

VRA221 |

VSA221 |

VTA221 |

VUA221 |

VVA221 |

VWA221 |

VXA221 |

VYA221 |

VZA221 |

ISOK15V |

|

VRA221Z |

VSA221Z |

VTA221Z |

VUA221Z |

VVA221Z |

VWA221Z |

VXA221Z |

VYA221Z |

VZA221Z |

ISOK15W |

|

VRA251T |

VSA251T |

VTA251T |

VUA251T |

VVA251T |

VWA251T |

VXA251T |

VYA251T |

VZA251T |

ISOK15X |

|

VRA251 |

VSA251 |

VTA251 |

VUA251 |

VVA251 |

VWA251 |

VXA251 |

VYA251 |

VZA251 |

ISOK15Y |

|

VRA252 |

VSA252 |

VTA252 |

VUA252 |

VVA252 |

VWA252 |

VXA252 |

VYA252 |

VZA252 |

ISOK15Z |

|

VRA301 |

VSA301 |

VTA301 |

VUA301 |

VVA301 |

VWA301 |

VXA301 |

VYA301 |

VZA301 |

ISOK20D |

|

VRA321 |

VSA321 |

VTA321 |

VUA321 |

VVA321 |

VWA321 |

VXA321 |

VYA321 |

VZA321 |

ISOK20E |

|

VRA322 |

VSA322 |

VTA322 |

VUA322 |

VVA322 |

VWA322 |

VXA322 |

VYA322 |

VZA322 |

ISOK |

|

VRA323 |

VSA323 |

VTA323 |

VUA323 |

VVA323 |

VWA323 |

VXA323 |

VYA323 |

VZA323 |

ISOK |

|

VRA324 |

VSA324 |

VTA324 |

VUA324 |

VVA324 |

VWA324 |

VXA324 |

VYA324 |

VZA324 |

ISOK20H |

|

VRA351 |

VSA351 |

VTA351 |

VUA351 |

VVA351 |

VWA351 |

VXA351 |

VYA351 |

VZA351 |

ISOK20I |

|

VRA352 |

VSA352 |

VTA352 |

VUA352 |

VVA352 |

VWA352 |

VXA352 |

VYA352 |

VZA352 |

ISOK20J |

|

VRA361 |

VSA361 |

VTA361 |

VUA361 |

VVA361 |

VWA361 |

VXA361 |

VYA361 |

VZA361 |

ISOK20K |

|

VRA362 |

VSA362 |

VTA362 |

VUA362 |

VVA362 |

VWA362 |

VXA362 |

VYA362 |

VZA362 |

ISOK |

|

VRA421 |

VSA421 |

VTA421 |

VUA421 |

VVA421 |

VWA421 |

VXA421 |

VYA421 |

VZA421 |

ISOK |

|

VRA422 |

VSA422 |

VTA422 |

VUA422 |

VVA422 |

VWA422 |

VXA422 |

VYA422 |

VZA422 |

ISOK20N |

|

VRA431 |

VSA431 |

VTA431 |

VUA431 |

VAV431 |

VWA431 |

VXA431 |

VYA431 |

VZA431 |

ISOK20O |

|

VRA441 |

VSA441 |

VTA441 |

VUA441 |

VVA441 |

VWA441 |

VXA441 |

VYA441 |

VZA441 |

ISOK20P |

|

VRA442 |

VSA442 |

VTA442 |

VUA442 |

VVA442 |

VWA442 |

VXA442 |

VYA442 |

VZA442 |

ISOK20Q |

VUA521---(K

PUA71------NVA

PRA

VH25

NXA

VH25

VH

VP40

VP40D

VP

VM

K30D-G

K

K

PM2/NRA82(P

BC03 K

PM3

P15

L15 P25

ISO20T ISO08 P358

K15

K25

K35

M510

M520

M10

M15

M20

K40

SU

NTA920A

NTA920