- Home > Products Catalog > Turning > Turning inserts

- Turning inserts

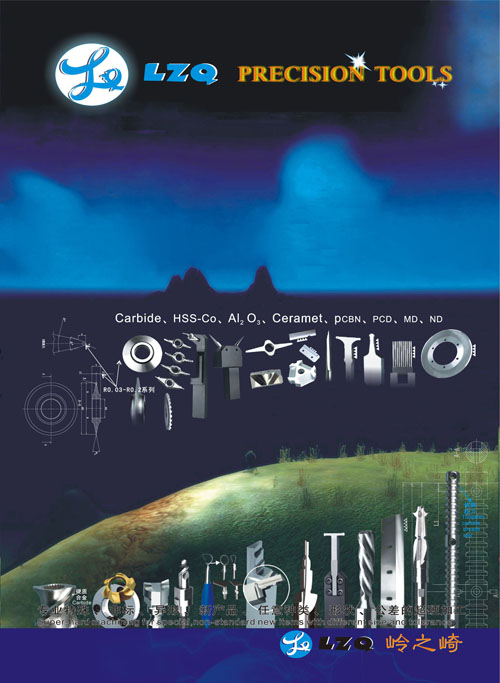

PU turning inserts,carbide tools

Model:A-grade

|

|||||

|

E-samples: P189 |

Details

PU turning inserts,carbide tools

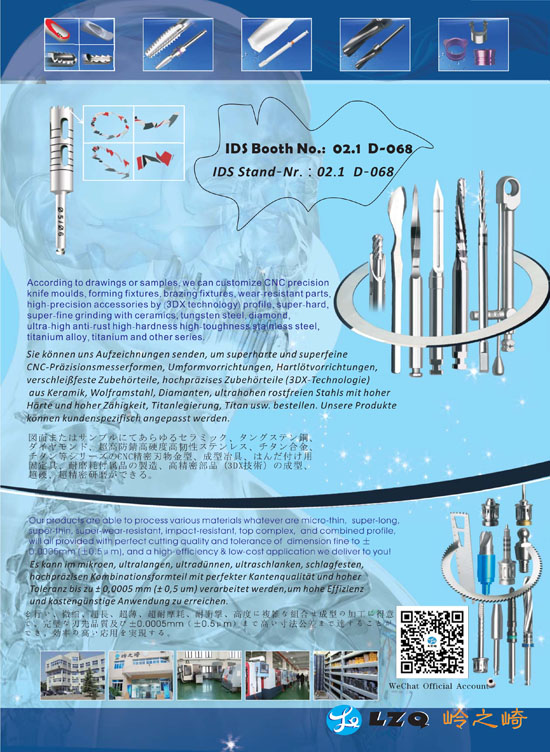

We adopt various business cooperation mode either royalty or part-time, and media promotion at different time period, as well as technical support and wholesale to middle-scale or large-scale enterprises or agency, even OEM processing as per customers' requirements. From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

| P20 | UC6010 | TS325 | AC2000 | CA225 | JC215 | GM20 | GC4025 | KC792M | TN250 |

| UC6025 | T725X | ST20E | CR600 | JC325 | GM25 | GC225 | KC9025 | TPC15 | |

| U610 | GH330 | A30N | CR7025 | JC4030 | CY15 | GC120 | KC810 | TPC25 | |

| U625 | TX20 | CR9025 | SRT | EX35 | SM30 | KC850 | TK15 | ||

| STI20 | TX25 | SR20 | SMA | KC710 | TN25M | ||||

| UTI20T | UX25 | DX30 | KC935 | TN150 | |||||

| K45 K125 | TN200 | ||||||||

| K420 TTM | TTX | ||||||||

| K125M |

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance.

If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

(For high precision profile machining)

Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements… only produce in batch, can completely replace international first-class products, having higher performance/price ratio

We can produce special, compound, special-shaped super-large, super-small, super-long combined profile series of cutters according to requirements of drawings, samples, and size tolerance.

Indexable (profile ) cutting tool (grinding & non-grinding) Throw away finish turning (milling) inserts

Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements… only produce in batch, can completely replace international first-class products, having higher performance/price ratio.

For super high-wear-resistant and high hardness processing (HRC58°~68°)

We can also produce special and non-standard products according to the requirements of drawings, samples and dimension tolerance.

material explanation:

Indexable (profile ) cutting tool (grinding & non-grinding) Throw away finish turning (milling) inserts

Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements… only produce in batch, can completely replace international first-class products, having higher performance/price ratio.

For super high-wear-resistant and high hardness processing (HRC58°~68°)

We can also produce special and non-standard products according to the requirements of drawings, samples and dimension tolerance.

material explanation:

HRF 10 (For super high wear-resistant):

Ultra micro-grain quality carbide is ultra high wear resistant, but less impact-resistant.It is applied in mid and low speed light cutting of

various materials that require ultra high wear resistance. Generally, it is applied in good work condition, stable cutting, good part fixture and

continuous light-duty machining. Comparing with general tungsten steel, it has 3~5 times more life time. Conforming to ISO K10~K25/P10~P25.

PR40:

PR40:

super micro-grain diamond tungsten steel, extensively applied, it can be applied in medium speed cutting and finish cutting of various materials with HRC≤28°. It has excellent impact resistance and general wear resistance, and has extensive application. Generally, it is applied for thicker cutting, discontinuous cutting and bad part fixture. After being coated, it has better result, can machine various materials of HRC50°. Comparing with ISOK20&general tungsten steel, it has 1-2 times lifetime and excellent wear resistance

We adopt various business cooperation mode either royalty or part-time, and media promotion at different time period, as well as technical support and wholesale to middle-scale or large-scale enterprises or agency, even OEM processing as per customers' requirements. From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.