- Home > Products Catalog > Other tools > other tools

- other tools

industry blade design

|

|||||

|

E-samples: P203 |

Details

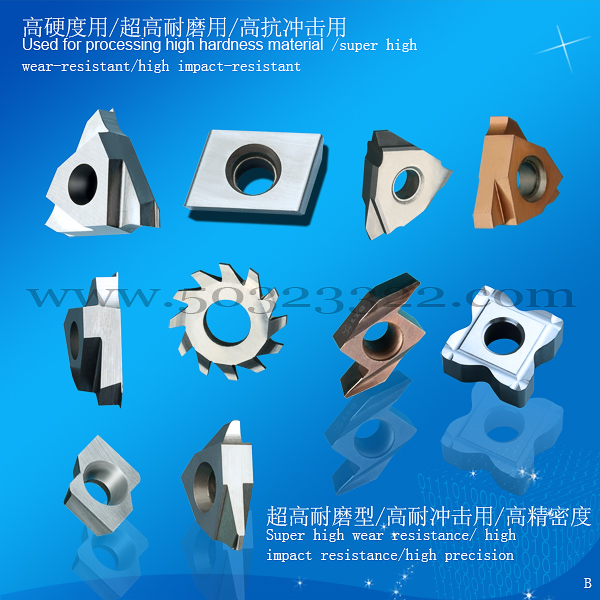

industry blade design

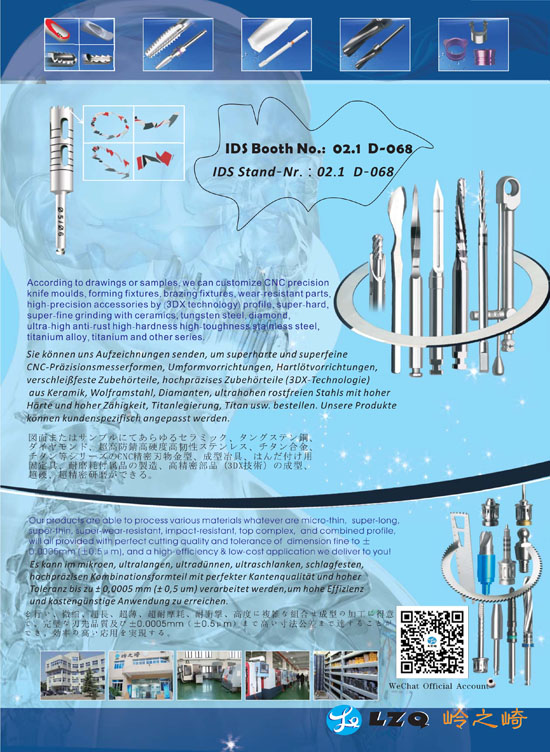

CNC lathe insert,Turning insert,lathe insert

(Super high-wear-resistant/high-impact-resistanapplication)

Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements… only produce in batch, can completely replace international first-class products, having higher performance/price ratio.

ASP60C :Imported super high wear-resistant high-grade high cobalt powder steel, quenched treatment:HRC70°±2°, with excellent wear resistance and impact resistance. Comparing with HSSE\HSS-AL and HSSCo, it has 4~8 times lifetime, and can guarantee uniformity and conformity rate of machined products. It is often applied in general equipment for machining various materials including Ni\Cr\Mo\Si\Ti) that are hard to machine like high temperature alloy\heat-resistant alloy\cast iron of nickel-vanadium-titanium alloy\stainless steel. It is excellent machining tool before heat treatment. It has excellent high temperature machining and comprehensive performance, and allows higher cutting speed. The higher the hardness of machined materials, the more remarkable the effect. Because its roughness is not so good, it is not suitable for discontinuous cutting or for using under processing system of insufficient rigidity, otherwise, cutter will be hit or chipping will happen.

VRA201: Imported ultra micro-grain quality carbide, with excellent impact-resistance and general wear-resistance. Generally applied in worse or general equipment to machine materials of lower hardness (HRC≤25°), discontinuous cutting and worse part fixture. Conforming to ISO K25, can replace machining of materials like M42, ASP60, MPM, HSSCo10 etc, and can get 4-6 times lifetime, it has higher performance/price ration. Comparing with SKH51, it has 15-25 times lifetime and durability.

MR11(MR12): ultra micro-grain diamond tungsten steel has excellent wear resistance and ideal impact resistance. It is applicable for high speed low feed machining of various materials with HRC25°-48°. It is the ideal machining tooling for thermal refining of materials, so it is extensively applied; comparing with general tungsten steel, it has 2-4 times lifetime. Generally it is applied in good and stable working conditions, good part fixture and continuous high speed light cutting. After being coated, it has better result, can machine various materials of HRC60°. Comparing with (ISOP15-P30/K15-K30), it is often applied in CNC equipment to machine various material (including Ni, Cr, Mo, Si, Ti etc.) that is hard to machine like high temperature alloy\heat-resistant alloy\cast iron of nickel-vanadium-titanium alloy\stainless steel. It is excellent machining tool before heat treatment and after thermal refining. It has excellent high temperature machining and comprehensive performance, and allows higher cutting speed. (general linear speed is ≥ 120M), low feed is required. The higher the hardness of machining materials, the better the result. Because its toughness is not so good, it is not suitable for continuous cutting or for using under little shaking, jumping condition of insufficient rigidity, otherwise, cutter will be hit or chipping will happen.

| P30 | UC6025 | GH330 | AC3000 | CA335 | JC215 | CY30 | GC4025 | KC935 | TN250 |

| US735 | T325 | AC304 | PR630 | JC325 | CY250 | GC235 | KC850 | TN35 | |

| U625 | TX30 | A30N | PR660 | JC4030 | HC844 | GC4035 | KC710 | TN25M | |

| UP20M | UX30 | A30 | PR930 | SR30 | EX35 | GC-A | CG4 GK | TPC25 | |

| STI30 | CR9025 | DX30 | EX40 | SM30 | K2885 | TPC35 | |||

| UTI20T | PW30 | DX25 | S30T | K420 | TN450 | ||||

| DX35 | KM TTR | TTM | |||||||

| K600 GX | TTR |

Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements… only produce in batch, can completely replace international first-class products, having higher performance/price ratio.

ASP60C :Imported super high wear-resistant high-grade high cobalt powder steel, quenched treatment:HRC70°±2°, with excellent wear resistance and impact resistance. Comparing with HSSE\HSS-AL and HSSCo, it has 4~8 times lifetime, and can guarantee uniformity and conformity rate of machined products. It is often applied in general equipment for machining various materials including Ni\Cr\Mo\Si\Ti) that are hard to machine like high temperature alloy\heat-resistant alloy\cast iron of nickel-vanadium-titanium alloy\stainless steel. It is excellent machining tool before heat treatment. It has excellent high temperature machining and comprehensive performance, and allows higher cutting speed. The higher the hardness of machined materials, the more remarkable the effect. Because its roughness is not so good, it is not suitable for discontinuous cutting or for using under processing system of insufficient rigidity, otherwise, cutter will be hit or chipping will happen.

VRA201: Imported ultra micro-grain quality carbide, with excellent impact-resistance and general wear-resistance. Generally applied in worse or general equipment to machine materials of lower hardness (HRC≤25°), discontinuous cutting and worse part fixture. Conforming to ISO K25, can replace machining of materials like M42, ASP60, MPM, HSSCo10 etc, and can get 4-6 times lifetime, it has higher performance/price ration. Comparing with SKH51, it has 15-25 times lifetime and durability.

MR11(MR12): ultra micro-grain diamond tungsten steel has excellent wear resistance and ideal impact resistance. It is applicable for high speed low feed machining of various materials with HRC25°-48°. It is the ideal machining tooling for thermal refining of materials, so it is extensively applied; comparing with general tungsten steel, it has 2-4 times lifetime. Generally it is applied in good and stable working conditions, good part fixture and continuous high speed light cutting. After being coated, it has better result, can machine various materials of HRC60°. Comparing with (ISOP15-P30/K15-K30), it is often applied in CNC equipment to machine various material (including Ni, Cr, Mo, Si, Ti etc.) that is hard to machine like high temperature alloy\heat-resistant alloy\cast iron of nickel-vanadium-titanium alloy\stainless steel. It is excellent machining tool before heat treatment and after thermal refining. It has excellent high temperature machining and comprehensive performance, and allows higher cutting speed. (general linear speed is ≥ 120M), low feed is required. The higher the hardness of machining materials, the better the result. Because its toughness is not so good, it is not suitable for continuous cutting or for using under little shaking, jumping condition of insufficient rigidity, otherwise, cutter will be hit or chipping will happen.

- Previous:CBN brazed lathe tool

- Next:industry blade