- Home > Products Catalog > Other tools > other tools

- other tools

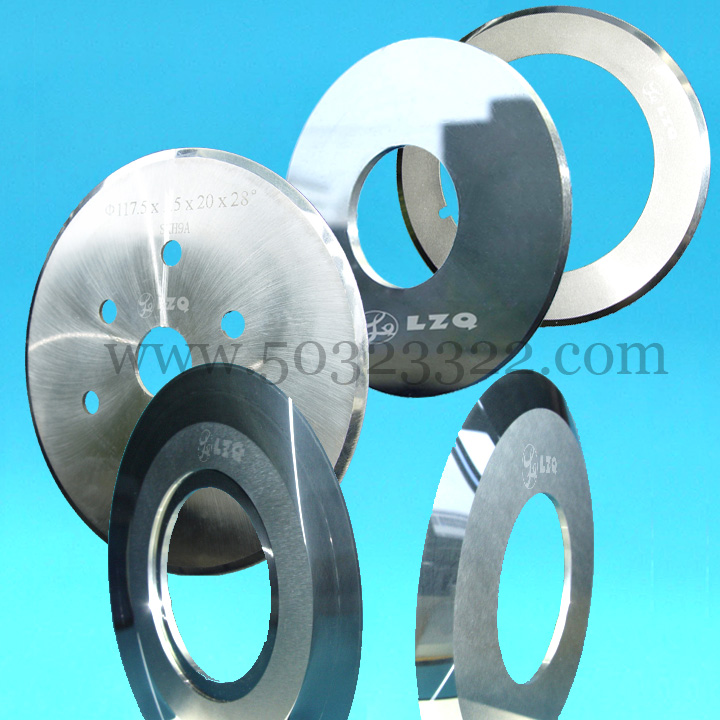

Cutting disks and shaping tools for the glass indu

|

|||||

|

E-samples: P235 |

Details

Cutting disks and shaping tools for the glass industry

(stainless/wear-resistant/high precision)

(N10 HTI10 TH10 EH10 KG10 K10K313 )

(stainless/wear-resistant/high precision)

|

★Indication of grinding wheel: the user shallindicate type of abrasive material, grain size, combination, concentration (density), binder, quantity etc.

|

||

|

★If there is any special requirement, we can produce according to drawings, samples or size tolerance.

|

| K10 | MB710 | BN600 | BX950 | KBN900 | JBN330 | |||

| MB730 | BN700 |

(M20 GM127 CNX725 RW2110)

(K20 G-10 CYC600 YG6 )

(S10 EH510 H10F K313 )

SDC

CBN

CBNC

CBN

CBNC

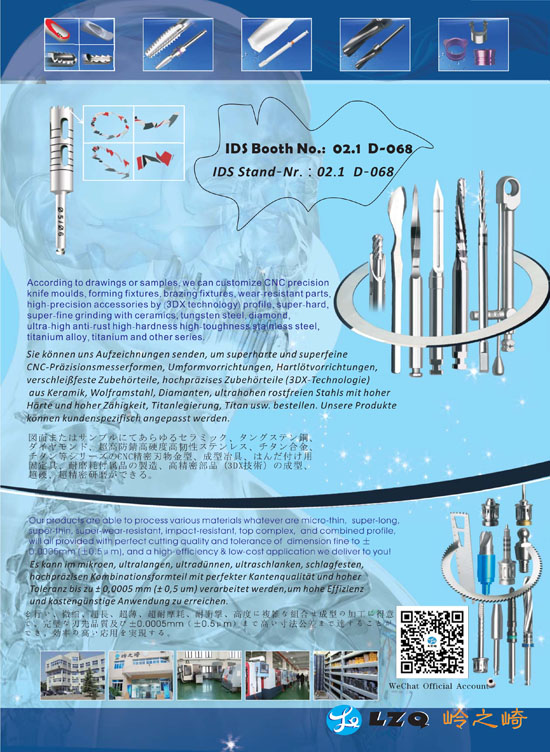

We adopt various business cooperation mode either royalty or part-time, and media promotion at different time period, as well as technical support and wholesale to middle-scale or large-scale enterprises or agency, even OEM processing as per customers' requirements. From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

- Previous:medullary space reamer

- Next:Broaching tool,Hard alloy push broach