- Home > Products Catalog > Other tools > other tools

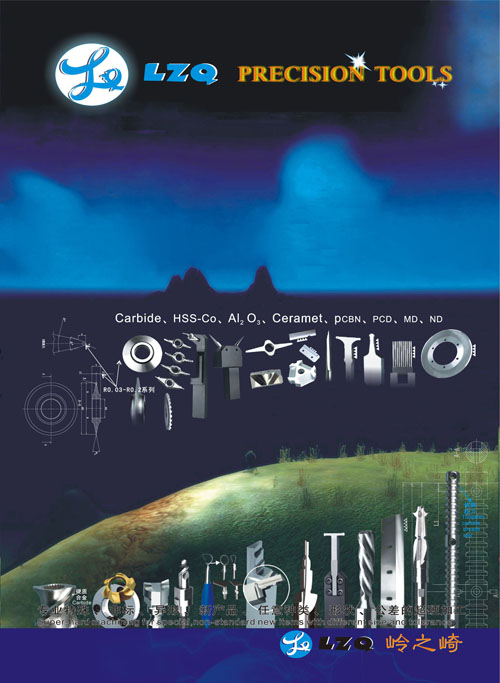

- other tools

cutting blade for the leather, round blade for the

|

|||||

|

E-samples: P51 |

cutting blade for the leather, round blade for the cloth,cutting blade for the circuit board

(Super high wear-resistance /high impact-resistance/high precision)

We can produce profile circular cutters of multi-angle,sharpness, thickness, inner and out diameter, material,

and profile according to drawings, samples.

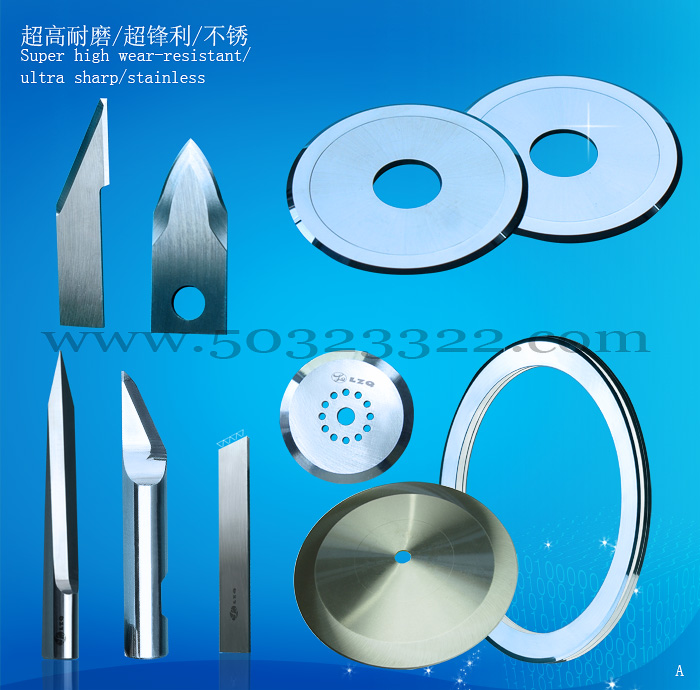

Cutting blade, fiber cleaver blade, glass cutter, quartz cutter, round cutter

Super high wear-resistant/super sharp/stainless

We can produce profile circular cutters of multi-angle,sharpness, thickness, inner and out diameter, material, and profile

according to drawings, samples.

P01 U66 T715X AC1000 CR7015 JC110 GH05 GC415 KC910 TN150

CA110 SRN HC5000 GC4015

(N10 HTI10 TH10 EH10 KG10 K10K313 )

ASP60C :

imported ultra high wear-resistant high-grade high cobalt powder steel, quenched:HRC70°±2°, with excellent wear resistance

and impact resistance. Comparing with HSSE\HSS-AL and HSSCo, it has 4~8 times lifetime, and can guarantee uniformity and

conformity rate of machined products. It is often applied in general equipment for machining various materials including

Ni\Cr\Mo\Si\Ti) that are hard to machine like high alloy\heat-resistant alloy\cast iron of nickel-vanadium-titanium

alloy\stainless steel. It is excellent machining tool before heat treatment. It has excellent high temperature machining and

comprehensive performance, and allows higher cutting speed. The higher the hardness of machined materials, the more

remarkable the effect. Because its roughness is not so good, it is not suitable for discontinuous cutting or for using under

processing system of insufficient rigidity, otherwise, cutter will be hit or chipping will happen.

VRA201:

Imported ultra micro-grain diamond tungsten steel, with excellent impact-resistance and general wear-resistance. Generally

applied in worse or general equipment to machine materials of lower hardness (HRC≤25°), discontinuous cutting and worse

part fixture. Conforming to ISO K25, can replace machining of materials like M42, ASP60, MPM, HSSCo10 etc, and can get 4-6

times lifetime, it has higher performance/price ration. Comparing with SKH51, it has 15-25 times lifetime and durability.

MR11: (For high wear-resistant application)

Ultra micro-grain quality carbide has property of excellent wear resistance and ideal impact resistance. It is applied in

mid, high speed intermediate cutting machining of various materials that HRC 28°~48°. It is an ideal machining tooling for

finish machining and material tempering, and it is extensively applied. Comparing with general tungsten steel, it has 2~3

times more lifetime. Generally it is applied in good and stable work conditions, good part fixture and continuous mid, high

speed light-duty cutting. After being TiALN coated, it has better performance, can machine various materials of HRC 60°

Conforming to ISO K10~K30/P10~P30. It is often applied in CNC equipment to machine various hard-machining materials

(containing Ni, Cr, Mo, Si, Ti etc.) like high temperature alloys, heat-resistant alloys, Ni-V-Ti alloys, cast iron,

stainless steel etc., ultra excellent machining tools before heat-treatment and after tempering. High temperature machining

and integrated property is good, allowing highest cutting speed (generally linear speed is above 120M) and with low feed

requirement. The higher hardness of the machining material, the better performance. Due to its bad toughness, it is not

applicable for discontinuous cutting or for conditions in which process system's rigidity is not sufficient and there is

chattering, jumping, otherwise, the blade will be hit or chipping will happen.

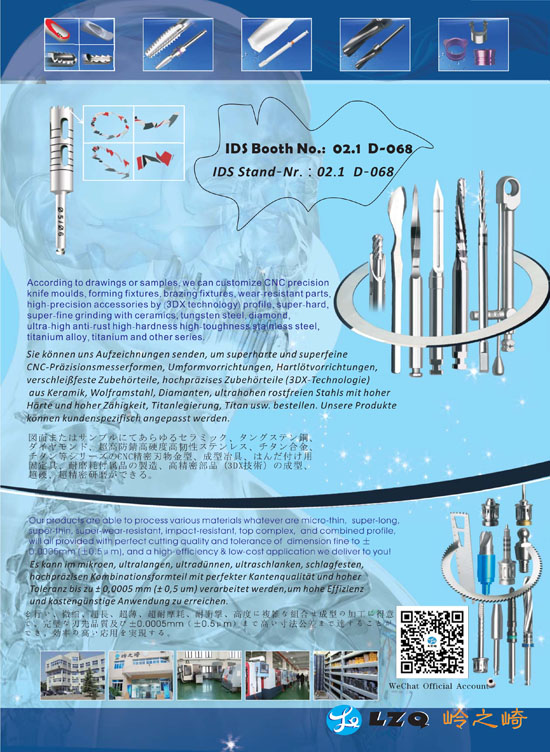

We adopt various business cooperation mode either royalty or part-time, and media promotion at different time period, as well

as technical support and wholesale to middle-scale or large-scale enterprises or agency, even OEM processing as per

customers' requirements. From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class

products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can

replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design

revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-

performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size

tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value

is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is

the processed material and its HRC?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with

different precision technology, so as to realize high efficiency application.