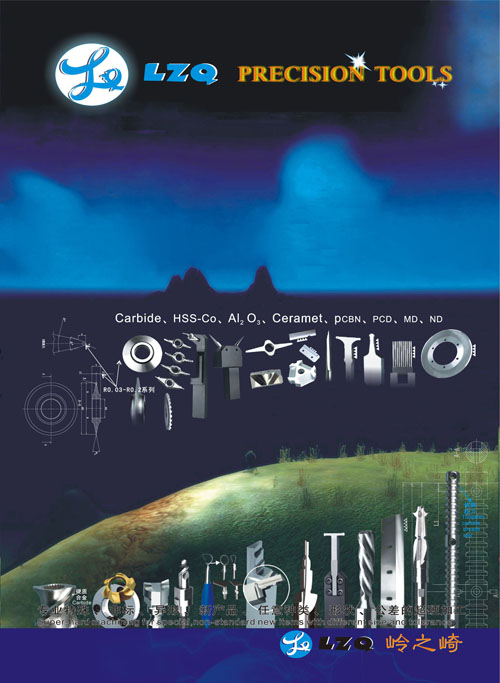

- Home > Products Catalog > Other tools > other tools

- other tools

Milling Bur 1.5 A XL Abutment

a

|

|||||

|

E-samples: P144 |

Details

Milling Bur 1.5 A XL Abutment

The photos and introductions belong to our factory,

Copying, downloading and reprinting unscrupulously is prohibited!

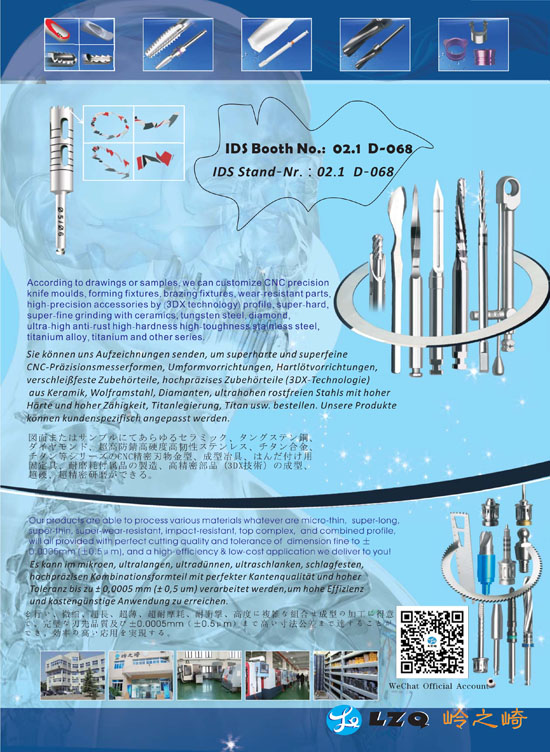

We keep around RMB 8~10 Million turnover stock articles such as raw material ,semi-products, finished products in ordinary year , we are capable to produce according to drawing or sample provided by customer, so as to present you a favorable cost-performance ratio…Welcome to visit our factory。

I am very glade to tell you that we are very good at producing these zironia mills and stylus. Please check my attachment for the pictures of our products. These products are exported all the year around and can replace the original ones imported from Germany. Our products are made of raw material imported from Germany and manufactured by the CNC machine bought from Switzerland at the price of RMB 3,000,000. The tolerance of the zirconia mills can be +0/-0.005 mm and the tolerance of the overall length can be :47 +0/-0.03 mm(46.97~47mm)In this way, it is not necessary for you to take some time to adjust the mills when replacing and install them directly for your use. What’s more, the cutting-edge is mirror surface grinding.

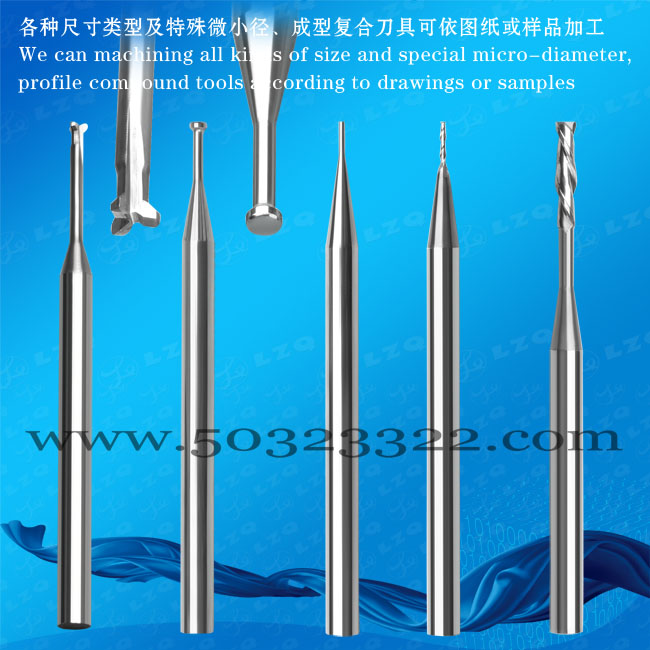

As you know, the flute number is usually two for size φ1.0(R0.5)and the flute number is usually three for sizeφ2.0(R1),φ3.0(R1.5)and φ4.0(R2.0).Some customers only want the mills and the corresponding stylus. And some customers require corresponding plastic rings which is for fixing the position. Please tell us the height of the fixing position for the ring if you require assembling the ring because different customers have different requirements for this.

For the mills with common fluent length, the mills usually have whole flute. However, there will be a thin tube in the middle of the mills if the flute length is very long. For example, for size2.0, the flute length is 5.0 and the length of the thin tube will be 10mm. The production cost will be higher if the flute length is very long.

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC? Work piece drawing and notes, and please supply us new and old bestperformed samples.

Samples: Is it easy to blunt or break or other problems?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

- Previous:Diamond bur

- Next:Amann automatic equipment bur