- Home > Products Catalog > Other tools > other tools

- other tools

Bone cross driver

|

|||||

|

E-samples: P144 |

Details

Bone cross driver

The photos and introductions belong to our factory,

Copying, downloading and reprinting unscrupulously is prohibited

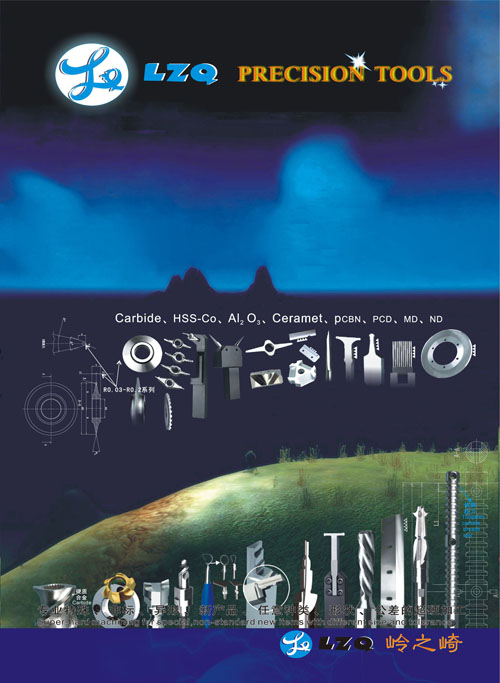

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance.

If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 8~10 Million turnover stock articles such as raw material ,semi-products, finished products in ordinary year , we are capable to produce according to drawing or sample provided by customer, so as to present you a favorable cost-performance ratio…Welcome to visit our factory.

We can produce different size tolerance and compound profile products according to drawings and samples.

Product Description

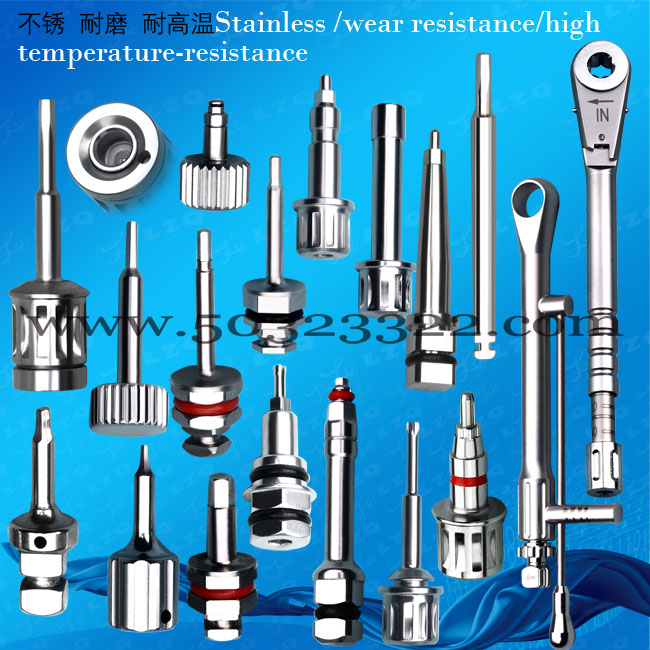

(Sharp,wear-resistant,high precision and special profile grinding)

Products:

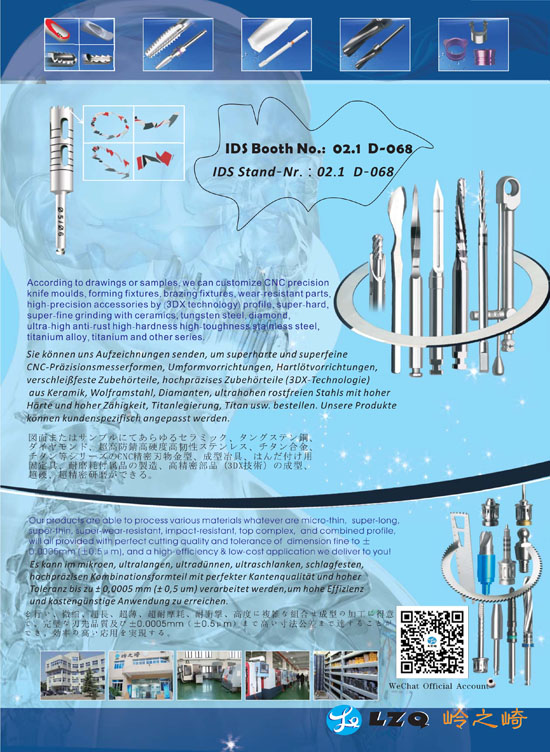

Orthopedic drill tool can be served according to the specific drawing size or sample. That is to say, all kinds of specific and complicated profile lathe can be produced. As to the Arthroscopy Plane Blade, we can serve it with all kinds tooth. Such as Shaver Blades and burrs , Incisor Plus Elite Blades and Helicut Burr, Which edges has been smooth grinded. Thus, it will be very sharp and the burr will be operated lightly, soft tissue will be cut effectively and accurately. As a result, we can chip smoothly ,reduce congestion, save operation time andreduce patient suffering.

By way of super hard and super finish grinding for harden material after heat treatment, we can produce any type of shank and satisfy your requirement of any hole diameter, wall thickness, thread form, number of teeth, cutting edge shape, cutting edge type, structure of cutting edge, angle, helix angle.

We can customize for you according to your samples or drawings for any manufacturing of ceramic, carbide, stainless high-speed steel, stainless steel, titanium alloy, titanium diamond etc series , high precision combination profile fixtures, brazed jigs and fixtures, wear-resistant parts, high-precision parts (3DX technology) profile super-hard and super-fine grinding.

Packaging & Shipping

1、Carton packaging

2、Other parts are packed in wooden case

3、If any special requirements, we will pack it as requested

Our Services

Best Service

Company Information

LZQ is an excellent OEM factory for manufacturing high precision and full finish grinding medical tools, cutters, fixtures, accessories as well as special new products. At present we are the OEM factory for suppliers who supply products of world-class brand; our main customers are also the manufacturers of medical tools and fixtures. We have been engaging in manufacturing the non-standard tooling and dies, profile fixtures and stainless steel or carbide brazed jigs and fixtures for the production of accessories in industry of airplane, naval vessels and automobile for a long time. With above advantages, we have gradually built and continued to improve advanced and comprehensive production system and enhanced all kinds of manufacturing and processing ability with precision technology. And with above production conditions, we realize the manufacturing for all kinds of tools, fixtures and accessories for medical use with processing way of high precision, high complexity and combination profile geometry. And we can manufacture according to your required dimensions, tolerances and other requirements for comprehensive profile processing of super complex and precision shape. The tools and cutters can have depth marking, different color code, different color coating, internal cooling hole and etc. We can meet any of your requirements if you like.

LZQ can realize the purpose of spreading medical tools for their application based on your design ability and idea. Therefore, you can set up your own systems for the tools, fixtures and accessories. So long as you have technical CAD drawing or 3D drawing or sample with best effect and even the woodwork of your own design with indication of dimensions and tolerances, we can provide you super hard and finish grinding products with perfect cutting edge and tolerance up to ±0.0005mm(±0.5μ) by using the world-class high quality material you require with world first-class CNC Processing Center, Super High-Speed Compound Grinding- Turning Center(3DX technology) referring to your drawings or samples and our products are of very high cost-performance!

LZQ is the OEM factory mainly for complicated, profile and precision tools, and normally doesn't participate in the design and application of medical tools and related certificate service . We will use any kind of imported high quality materials and grind to shape directly after heat treatment or we will grind the materials after heat treatment supplied by customers. If you have best performed samples and mark important demands to us, we will check any parameter you are worried about, we will improve and grind to shape.

We adopt various business cooperation mode either royalty or part-time, and media promotion at different time period, as well as technical support and wholesale to middle-scale or large-scale enterprises or agency, even OEM processing as per customers' requirements. From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC? Work piece drawing and notes, and please supply us new and old bestperformed samples.

Samples: Is it easy to blunt or break or other problems?

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

- Previous:Bone instrument cross driver

- Next:Bone cross driver