Page 267 - 岭之崎医疗器械

P. 267

医用工具及配件系列( 、内 、关 刀) (超锋利刃口&超高防锈(AA)&超高耐磨&超高精密度内外配合)

Medical tools and parts series( torhinolaryngologic, (Ultra-sharp cutting edge & ultra-high anti-rust (AA) & ultra-high wear

endoscopic, arthroscopic shaver blades) -resistant & ultra-high precision cooperation of inner tubes and outer tubes)

(超鋭利刃 &超防錆(AA)&超耐磨耗&超精度 外接合)

医療 及び部品 リー ( 刃)

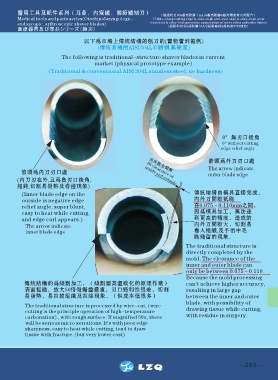

以下为市场上传统结构的 刀的(实物实 范 )

(传统常规的AISI304L不锈钢,无硬度)

The following is traditional-structure shaver blades in current

market (physical prototype example)

(Traditional & conventional AISI 304L stainless steel, no hardness)

0°无刃口后

ithout cutti g

e

edge relie a gle

头为

头为外刀刃口处

he arro i dicate he a

内刀刃口处

头为内刀刃口处 fit clearance of

内外配合间

outer blade edge

(内刀刃在外,且为 刃口后 ,

inside and outside

超钝,切割易发热及 现象)

传统结构由模具 接完成,

(Inner blade edge on the

内外刀间 只能

outside is negative edge

relief angle, super blunt, 在0.075 0.110mm之间,

easy to heat while cutting, 因为模具加工,无法达

and edge curl appears.) 到更高的精度,造成的

The arrow indicate 内外刀间 大,切割易

inner blade edge 入组织,及手术中

点 的现象。

The traditional structure is

directly completed by the

mold. The clearance of the

inner and outer blade can

only be between 0.075 0.110.

Because the mold processing

传统结构的为 割加工,( 割属高温 化的原理作业) can't achieve higher accuracy,

表面粗 , 大50倍微 重,刃口锋利性很差,切割 resulting in large gap

易发热,易 组织及 丝现象。(但成本低很多) between the inner and outer

blade, with possibility of

The traditional structure is processed by wire-cut, (wire

cutting is the principle operation of high-temperature drawing tissue while cutting,

carbonation) , with rough surface. If magnified 50x, there with residue in surgery.

will be serious micro serrations. It's with poor edge

sharpness, easy to heat while cutting, tend to draw

tissue with fracture. (but very lower cost)

—263—