- Home > Products Catalog > Other tools > other tools

- other tools

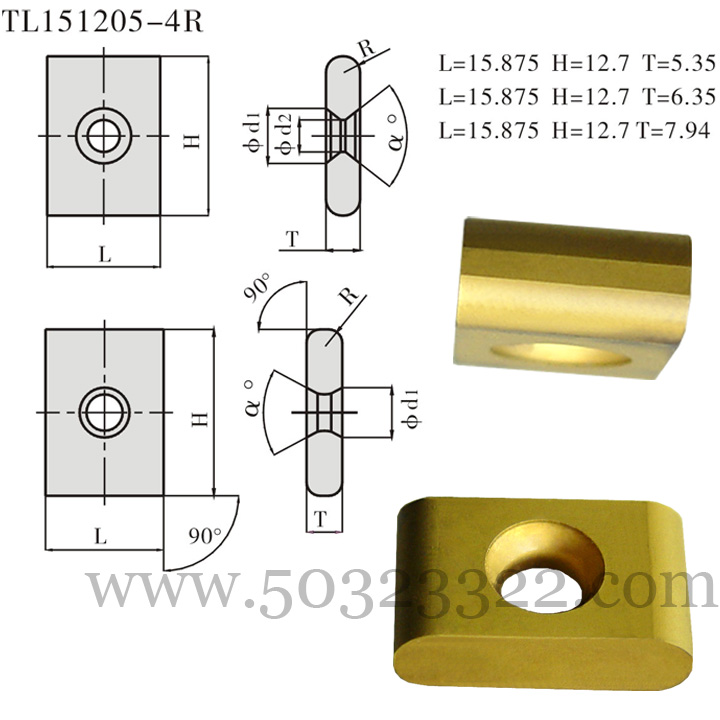

Carbide indexable inserts

|

|||||

|

E-samples: P195 |

Carbide indexable inserts(Super high-wear-resistant/high-impact-resistant application)

Comparison table for general brand (material) of diamond tungsten steel

★Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements… only produce in batch, can completely replace international first-class products, having higher performance/price ratio

| K20 | Uc6010 | T5020 | AC500G | CR300 | JC10 | GF30 | GC4025 | KC9025 | HK150 | IC2 | TX150 | CN15 | 702 |

| UP20M | T1020 | AC2000 | CR7015 | JC215 | WH20 | GC415 | KC992M | HK15M | IC20 | T15M | CN20 | CQ2 | |

| F515 | GH120 | EH2022 | KW10 | JC610 | GC435 | KC250 | HK35 | IC10 | T25M | CN25 | CQ22T | ||

| HTI20T | G2F | EH20 | JC5015 | HM | KC730 | THM | TP200 | CN30 | CQ23 | ||||

| HTI20 | KS20 | G10E | KT9 | H20 | CG4 KFM | 890 | GM15 | CQ24 | |||||

| UTI20T | G2 | EH520 | CR1 | H13A | K313 KMF | HX | U222 | ||||||

| KG20 | K8735 | 883 | |||||||||||

| K715 | |||||||||||||

| K600 |

ISO: NO1/N05/N10/N15/N20/N25/N30/N35/N40/N45/N50/N55/N60/N65/N70/N75/N80/N85

LZQ: /NRB10Z/NRB10/Mr11/KR121/MR12/HUF10/MR12T/KR141/KR301/NRA61

/NRA62/NRA71/KRA720

Mitsubishi Material: HTI10

Toshiba Tungaloy: H1/EH10/EH510/G10E/EH20/EH520

Sumitomo Eiectric: H1/H2/EH10/EH510/G10E/EH20/EH520

DIJET: KG03/KG10/KT9/CR1/KG20/KG30

Sandvik: H10/H13A

Kennametal: K605/K10 K313/KF1 KM1/K110M/THM/THM-U/K715/KMF/K600/G13/THR

Seco Tools: 890/H15/HX KX/883 H15/H25MU11/H25

ISO: S01/S05/S10/S15/S20/S25/S30/S35/S40/S45/S50/S55/S60/S65/S70/S75/S80/S85

LZQ: NRB10/SR10/SR10T/MR11/MR12/HUF10/MR12T/PR15/PRA5/PRA8/PU40/PUA5

Mitsubishi Material: RT9005/RT9005/RT9010/RT9010/TF15/TF15

Toshiba Tungaloy: TH10/KS20

Sumitomo Eiectric: EH10/EH510/EH20/EH520

DIJET: KG03/FZ05/KG10/FZ15/KG20/KG30

Sandvik: H10/H10A/H10F/H13A

Kennametal: K10/K313/THM/K715/KMF/G13 K600/THR

Iscar: MU11

Seco Tools: 890/890 883/HX H25/PR40

Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements only produce in batch, can completely replace international first-class products, having higher performance/price ratio.

LZQ is possessed of cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology , so as to realize high efficiency application.

From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

Referencing to the page footer, please provide your sample and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency, when you make inquiry. What is the processed material and its HRC