- Home > Products Catalog > Medical Tools > Other medical tools

- Other medical tools

lindemann drill stopper,final drill stopper

Details

lindemann drill stopper,final drill stopper

(stainless/wear-resistant/high precision)

(N10 HTI10 TH10 EH10 KG10 K10K313 )

(M20 GM127 CNX725 RW2110)

(K20 G-10 CYC600 YG6 )

(S10 EH510 H10F K313 )

(K10 2A5 H216T H10T G-920 CX2515 YG6A GW620H UH10 CS310 BK6M 741 )

(stainless/wear-resistant/high precision)

| P10 | NX33 | NX33 | N308 | T12A | TC30 | LN10 | CH350 | CT525 | KT125 | TTI-05 | CM |

| AP25N | AP25N | NS520 | T130Z | TC40 | CX50 | CZ25 | CC670 | KZ205 | TTI-15 | C15M | |

| NX2525 | NX2525 | GT530 | T1200A | TN60 | NIT | CZ1025 | CT5015 | KT175 | TTI-25 | ||

| NS530 | WX120 | TN6020 | CX75 | GC1525 | HT2 | R,G, | |||||

| WG300 | T2000Z | PV60 | KB90X | M,U | |||||||

| AT520 | PV7020 | KT195M | |||||||||

| AT530 | KT530M |

(N10 HTI10 TH10 EH10 KG10 K10K313 )

(M20 GM127 CNX725 RW2110)

(K20 G-10 CYC600 YG6 )

(S10 EH510 H10F K313 )

(K10 2A5 H216T H10T G-920 CX2515 YG6A GW620H UH10 CS310 BK6M 741 )

(Stainless /wear resistance/high temperature-resistance/high precision)

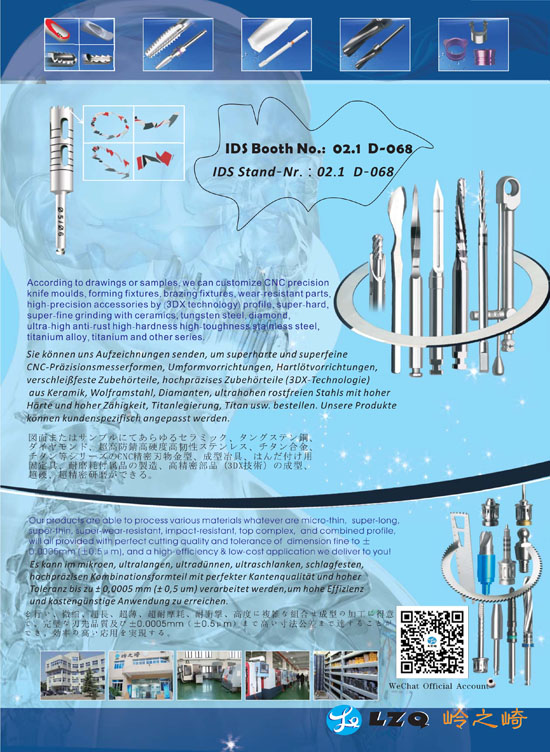

Products:Stainless bit,OT cutting Tool,Stainless Steel Tool,Stainless Steel Tools,Stainless steel needle drilling,Stainless steel screwdriver,Bone Drill,Screwdriver, Needle Drill, Medical bit, Profile drilling-mill forming stainless high speed steel, Carbide drilling-mill.

Products:Stainless bit,OT cutting Tool,Stainless Steel Tool,Stainless Steel Tools,Stainless steel needle drilling,Stainless steel screwdriver,Bone Drill,Screwdriver, Needle Drill, Medical bit, Profile drilling-mill forming stainless high speed steel, Carbide drilling-mill.

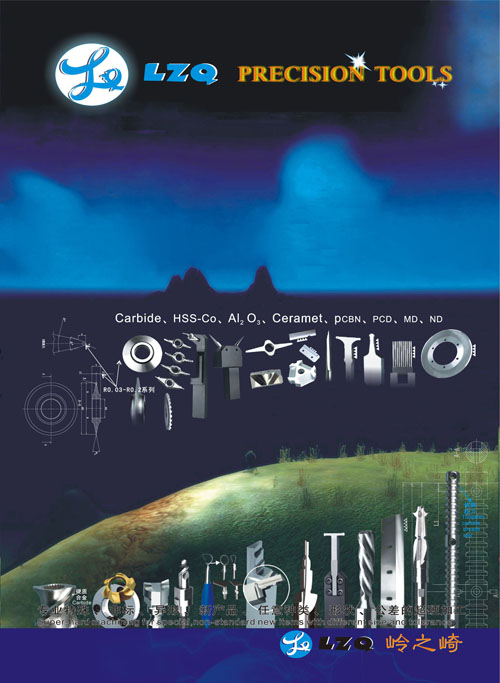

LZQ is an excellent OEM factory for manufacturing high precision and full finish grinding medical tools, cutters, fixtures, accessories as well as special new products. At present we are the OEM factory for suppliers who supply products of world-class brand; our main customers are also the manufacturers of medical tools and fixtures. We have been engaging in manufacturing the non-standard tooling and dies, profile fixtures and stainless steel or carbide brazed jigs and fixtures for the production of accessories in industry of airplane, naval vessels and automobile for a long time. With above advantages, we have gradually built and continued to improve advanced and comprehensive production system and enhanced all kinds of manufacturing and processing ability with precision technology. And with above production conditions, we realize the manufacturing for all kinds of tools, fixtures and accessories for medical use with processing way of high precision, high complexity and combination profile geometry. And we can manufacture according to your required dimensions, tolerances and other requirements for comprehensive profile processing of super complex and precision shape. The tools and cutters can have depth marking, different color code, different color coating, internal cooling hole and etc. We can meet any of your requirements if you like.

LZQ can realize the purpose of spreading medical tools for their application based on your design ability and idea. Therefore, you can set up your own systems for the tools, fixtures and accessories. So long as you have technical CAD drawing or 3D drawing or sample with best effect and even the woodwork of your own design with indication of dimensions and tolerances, we can provide you super hard and finish grinding products with perfect cutting edge and tolerance up to ±0.0005mm(±0.5μ) by using the world-class high quality material you require with world first-class CNC Processing Center, Super High-Speed Compound Grinding- Turning Center(3DX technology) referring to your drawings or samples and our products are of very high cost-performance!

LZQ is the OEM factory mainly for complicated, profile and precision tools, and normally doesn't participate in the design and application of medical tools and related certificate service . We will use any kind of imported high quality materials and grind to shape directly after heat treatment or we will grind the materials after heat treatment supplied by customers. If you have best performed samples

and mark important demands to us, we will check any parameter you are worried about, we will improve and grind to shape.

SKH4C: (a kind of high speed steel, which does not rust at all.)(Hardening treatment: HRC60°±2°)

This is super high hardness super mirror finish stainless high speed steel. It is characterized by excellent anti-rust, anti-corrosion, anti-worn (high hardness) and ideal impact resistance properties. It applies to a wide range. Its useful life is 3-6 times than normal stainless products. Moreover, AIS1440C and SUS440C are even better quality of incisiveness and much more excellent anti-worn properties. Under salt water circumstances, it's anti-rust capability could improve more than 10-20 times. Its quality is quite good and stable. we can produce extreme complex and accurate Holder profile.

This is super high hardness super mirror finish stainless high speed steel. It is characterized by excellent anti-rust, anti-corrosion, anti-worn (high hardness) and ideal impact resistance properties. It applies to a wide range. Its useful life is 3-6 times than normal stainless products. Moreover, AIS1440C and SUS440C are even better quality of incisiveness and much more excellent anti-worn properties. Under salt water circumstances, it's anti-rust capability could improve more than 10-20 times. Its quality is quite good and stable. we can produce extreme complex and accurate Holder profile.

SKH4B: (a kind of high speed steel, which does not rust at all.)(Hardening treatment: HRC58°±2°)

This is super high hardness super mirror finish stainless high speed steel. It is characterized by excellent anti-rust, anti-corrosion, anti-worn (high hardness) and ideal impact resistance properties. It applies to a wide range. Its useful life is 2-3 times than normal stainless products. Moreover, AIS1420C and SUS420C are even better quality of incisiveness and much more excellent anti-worn properties. Under salt water circumstances, it's anti-rust capability could improve more than 10-20 times. Its quality is quite good and stable. we can produce extreme complex and accurate Holder profile.

SKH2C:High antirust, super mirror stainless steel(HRC45°±2°), which is equal to SKH4C(HRC60°±2°) and has 5-10 times antirust performance salt mist resistance.

SKH4B: (a kind of high speed steel, which does not rust at all.)(Hardening treatment: HRC58°±2°)

This is super high hardness super mirror finish stainless high speed steel. It is characterized by excellent anti-rust, anti-corrosion, anti-worn (high hardness) and ideal impact resistance properties. It applies to a wide range. Its useful life is 2-3 times than normal stainless products. Moreover, AIS1420C and SUS420C are even better quality of incisiveness and much more excellent anti-worn properties. Under salt water circumstances, it's anti-rust capability could improve more than 10-20 times. Its quality is quite good and stable. we can produce extreme complex and accurate Holder profile.