Page 281 - 岭之崎医疗器械

P. 281

医用工具及配件系列( 、内 、关 刀)(超长型设计 )

Medical tools and parts series ( torhinolaryngologic, (超锋利刃口&超高防锈(AA)&超高耐磨&超高精密度内外配合)

endoscopic, arthroscopic shaver blades) (Ultra-sharp cutting edge & ultra-high anti-rust (AA) & ultra-high wear

(Super-long design ) -resistant & ultra-high precision cooperation of inner tubes and outer tubes)

医療 及び部品 リー リン ター 刃 (超鋭利刃 &超防錆(AA)&超耐磨耗&超精度 外接合)

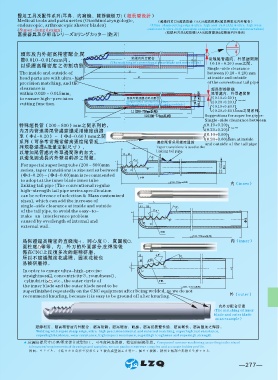

头部段内外超高精密配合,间

常规内外刀配合

0.010~0.015mm内, (The matching of conventional inner blade and outer blade) 常规 处内、外单 间

∅

∅

以保证高精密度之切割 能。 (0.10 0.20)mm之间。

Single-side clearance

The inside and outside of between (0.10 0.20) mm

head parts are with ultra-high at inside and outside

precision matching, and the of the conventional tail pipe

clearance is 超长型的建议:

within 0.010 ~ 0.015mm, 处内、外单 间

to ensure high-precision 超长型的建议:内外刀配合 ~~

cutting function. (Suggestions for super long type: ∅ (0.20+0.20)

The matching of inner blade and outer blade)

(0.10+0.20)

(0.10+0.60)

(0.20+0.60) mm之间系列。

Suggestions for super long type:

Single-side clearance between

特殊超长 (200 800)mm之间系列的, ~~

(

内刀内 接 处建议采用 度过 (0.20+0.20)

(0.10+0.20)

至( d-0.20) ( d-0.60)mm之间 (0.10+0

(0.20+0.60) mm at inside

系列(可参考常规常备高强度 系 接 采用 度过 接 采用 度过 (0.20+0

(0.10+0.60)

and outside of the tail pipe

列规格 &批量定制尺寸), a er tra sitio s is used at the

以 加 处内外单 间 的加大, li i g tail i e

以 因过长内外 易干 之 。 ∅

For special super long tube (200 800)mm ( d-0.6)mm之间系列

series, taper transitions to size series between ( d-0.2)mm~ d

( d-0.20) ( d-0.60)mm is recommended

to adopt at the inner blade inner tube

linking tail pipe (The conventional regular (308~778mm系列) 内(inner)

high-strength tail pipe series specification

can be reference of selection & Mass customized

sizes), which can add the increase of

single-side clearance at inside and outside

of the tail pipe, to avoid the easy-to-

make-an-interference problem

caused by overlength of internal and d

external wall.

(308~778mm系列)

为保证超高精密的 度- 、同心度 、 圆度 、 内(inner)

度 等

圆柱度 等等,内、外刀的外圆部分,在焊接后

需在CNC上 复多次的超精研磨,

所以不建议做 花处理,因 花后也

易被研磨 。

In order to ensure ultra-high-precise ∅

straightness , concentricity , roundness ,

-

cylindricity , etc., the outer circle of

y , e

the inner blade and the outer blade need to be (280~750mm系列)

superfinished repeatedly on the CNC equipment after being welded, so we do not

recommend knurling, because it is easy to be ground off after knurling. 外(outer)

内外刀配合示意

(The matching of inner

blade and outer blade

as an example)

超锋利刃、超高精密度内外配合、超高防锈,超高硬度、耐磨,超高抗冲击性能、超高韧性,超高强度之焊接。

Welding with super sharp edge, ultra-high precision internal and external matching, superhigh rust resistance,

superhigh hardness, wear resistance, high impact resistance, superhigh toughness and superhigh strength.

—277—